Introduction to Rogowski Coil TechnologyRogowski coils, also known as air-cored coils, have evolved from solenoids since their invention in 1912. Initially limited by low output voltage incompatible with early measuring devices, their adoption surged with advancements in sensor sensitivity. Today, solid-state electronics and microprocessor integration have expanded their applications, particularly in flexible Rogowski coil configurations. These innovative solutions offer superior AC current measurement compared to traditional iron core transformers (CTs), including split core current transformers, at competitive costs.

Challenges with Traditional Iron Core CTsWhile iron core CTs (both solid and split core) are widely used in permanent installations and portable test equipment, they face limitations:

Mechanical Constraints: Rigid clamp-on CTs struggle in crowded panels, often requiring multiple units for varying current ranges.

Alignment Dependency: Split core CT accuracy relies on precise jaw alignment, which is impractical in tight spaces or live circuits.

Safety Risks: Inductive kick during installation/removal and open-circuit secondary voltages pose hazards to personnel and equipment.

Circuit Distortion: CT impedance can alter low-impedance circuit behavior.

DC Saturation: Iron cores magnetize in DC environments, necessitating degaussing.

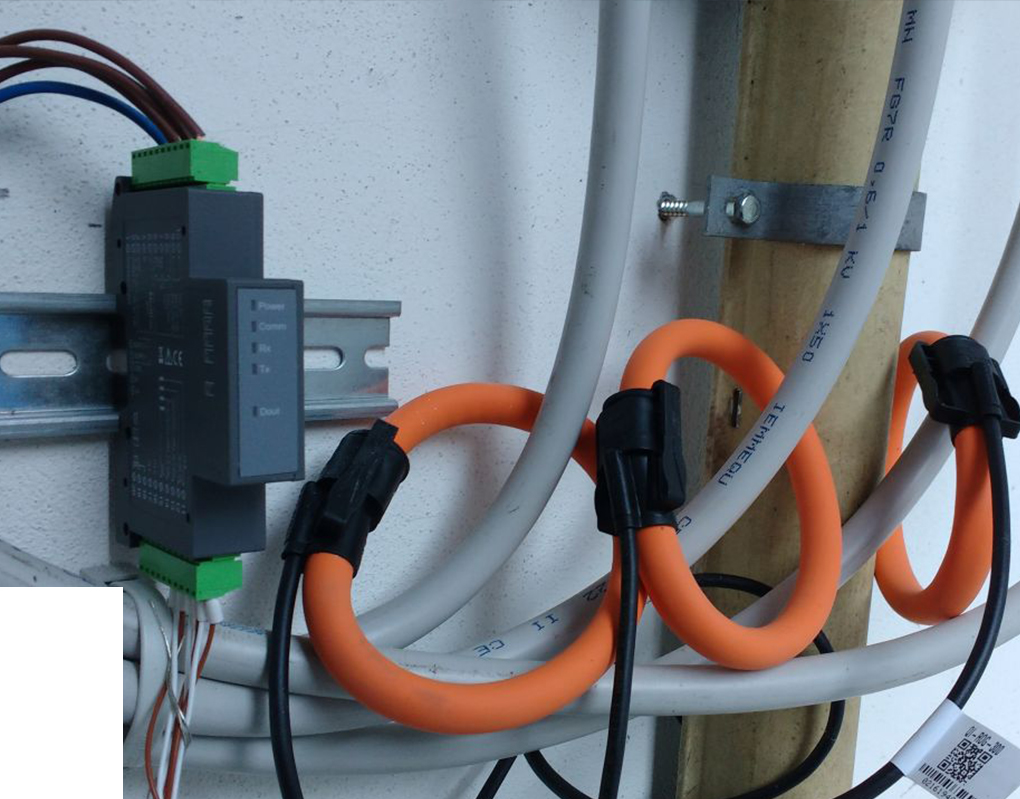

Advantages of Rogowski CoilsFlexible Rogowski-based current probes address these issues:

Space-Saving Design: Easily deployable in confined areas, unlike bulky split core current transformers.

Single-Probe Versatility: Lightweight designs cover wide current ranges, reducing equipment redundancy.

Safety: Low-voltage output eliminates inductive kick and open-circuit risks.

Non-Intrusive: No iron core ensures minimal circuit loading and immunity to DC saturation.

Theory of OperationRogowski coils operate on Faraday’s Law, generating an induced voltage proportional to the time-varying magnetic flux around a conductor. The coil’s flexible, non-ferrous core design ensures uniform sensitivity to primary current changes. The output voltage, expressed as:\ \(V = -K \cdot N \cdot A \cdot \frac{di}{dt}\)where K is a constant, N is turns per length, A is average turn area, and \(\frac{di}{dt}\) is the current derivative, requires integration to reconstruct the original current waveform. Modern Rogowski-based sensors, like Powerway’s solutions, include built-in integrators for accurate phase and amplitude reproduction.

Applications in Smart Metering and BeyondRogowski coil technology is pivotal in smart grid infrastructure, enabling reliable, high-precision current monitoring in smart meters. Their flexibility and safety make them ideal for energy management, industrial automation, and renewable energy systems.

Powerway Tech: Leading Rogowski Coil InnovatorsAt

Powerway Tech, we specialize in cutting-edge Rogowski coil solutions for diverse applications. Our products combine advanced engineering with user-friendly design, ensuring seamless integration into smart meters, industrial machinery, and power distribution networks. Explore our range of flexible and fixed Rogowski coils, split core current transformers, and smart meter to optimize your AC current measurement needs.